VP-SC Screw Conveyor

- Model: VP-SC

- Base Configuration Price: Starting at $1200

- Machine Material: Carbon Steel/Stainless Steel

- Screw Diameter: Typically ranging from 100mm to 500mm

- Screw Length: Variable, depending on the conveyor length, usually ranging from 2 meters to 20 meters

- Capacity: Variable, depending on the screw diameter, screw length, and material characteristics, usually ranging from 0.5 m³/h to 30 m³/h

- Features: Equipped with a durable screw mechanism, adjustable speed control, and versatile configurations for various material handling applications

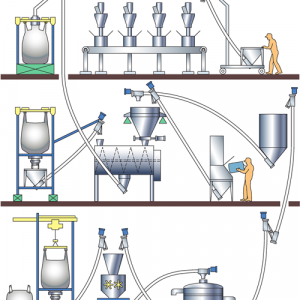

Description: The VP-SC Screw Conveyor is a reliable and efficient solution for material conveying needs. Constructed with high-quality carbon steel or stainless steel, it ensures durability and reliability in various industrial environments. With customizable screw diameters and lengths, it accommodates different material handling requirements, typically ranging from 100mm to 500mm in screw diameter and from 2 meters to 20 meters in screw length. Equipped with a durable screw mechanism and adjustable speed control, the VP-SC Screw Conveyor provides efficient and reliable material conveying, suitable for a wide range of applications in industries such as agriculture, food processing, and manufacturing. Upgrade your material handling process with the VP-SC Screw Conveyor today!

产品标题覆盖关键词产品标题覆盖关键词产品标题覆盖

VP-SC Screw Conveyor: Efficient Material Transport Solution

Introduction: Welcome to Vibepro’s Screw Conveyor, a reliable and versatile solution for transporting bulk materials in various industrial settings. Our Screw Conveyor is designed to efficiently move materials such as powders, granules, and flakes, offering seamless integration and reliable performance in your production processes.

Key Features:

- Robust Construction: The VP-SC Screw Conveyor is built with high-quality materials and precision engineering, ensuring durability and long-term reliability even in demanding operating conditions.

- Flexible Configuration: We offer customizable options for screw diameter, length, and pitch, allowing you to tailor the Screw Conveyor to your specific material handling requirements and facility layout.

- Efficient Material Transport: With its helical screw design, our Screw Conveyor ensures smooth and efficient material transport, minimizing material degradation and ensuring consistent throughput.

- Easy Integration: The VP-SC Screw Conveyor can be easily integrated into existing production lines or used as a standalone system, offering flexibility and versatility in material handling processes.

- Low Maintenance Requirements: Featuring a simple design and minimal moving parts, our Screw Conveyor requires minimal maintenance, reducing downtime and ensuring continuous operation in your facility.

Enhance Your Material Handling Efficiency with Vibepro: Upgrade to Vibepro’s Screw Conveyor and experience improved efficiency and productivity in your material handling processes. Contact us today to learn more about how our Screw Conveyor can benefit your production facility.

产品概述

文字–产品核心特点+工作原理+物料+核心的应用场景+工作原理图或者物料运动轨迹(下图)

产品特点

产品特点1

产品特点1

产品特点1

产品特点1

产品特点1

应用场景

应用场景

说明产品适用的行业和具体应用场景。

应用行业+物料名字

应用行业+物料名字

应用行业+物料名字

应用行业+物料名字

应用行业+物料名字

这是标题

这是标题

这是标题

这是标题

技术参数

技术参数表格,不知道怎么添加表格

售后及技术支持

这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。这是测试文本,单击 “编辑” 按钮更改此文本。

相关产品