-

Products

Tap Sieve Shaker · Laboratory Particle Size & Powder Analysis

-

Combined tapping + vibration, ideal for agglomerated powders

-

Up to 7 sieve decks for multi-grade particle size distribution

-

Simulates manual tapping; results compliant with ASTM / ISO standards

Tap Sieve Shaker · Laboratory Particle Size & Powder Analysis

-

Combined tapping + vibration, ideal for agglomerated powders

-

Up to 7 sieve decks for multi-grade particle size distribution

-

Simulates manual tapping; results compliant with ASTM / ISO standards

Product Overview

The tapping screen combines traditional vibratory screening with a mechanical tapping action to prevent caking and mesh clogging. Compact, easy to operate, and highly reliable, the device is widely used in research, quality control, and laboratory particle size analysis. It is also used for checking the particle size composition of common abrasives and grading superhard materials in industries such as geology, metallurgy, chemicals, construction, cement, and pharmaceuticals.

How It Works & Video Demo

Driven by a vibrating motor, the material undergoes vertical and radial rotation on the sieve. Simultaneously, a mechanical device taps the sieve cover at set intervals, causing the material to jump and flip. This accelerates particle flow through the sieve, ensuring accurate results for sticky powders. It’s commonly used in laboratory research screening. A demonstration video demonstrates the combination of tapping and vibration.

Built Around Your Workflow · Practical Innovation · Total Cost Control

Why Choose Our Circular vibrating screen

Efficient Anti-Clogging

Feature: Dual vibration + mechanical tapping drive

Data: ≥30% higher throughput for cohesive powders

Benefit: Reduces clogging, improves testing efficiency

Standardized Test Results

Feature: Compliant with ASTM E11 / ISO 3310 standards

Data: Accuracy ±2%

Benefit: Reliable results with traceable data

Multi-Deck Flexibility

Feature: 1–7 decks freely stackable

Data: Obtain 2–8 particle fractions in one run

Benefit: Saves time and minimizes repeated testing

Compact & Quiet

Feature: Small footprint with soundproof design

Data: Noise < 65 dB

Benefit: Suitable for labs and office environments

Transparent Delivery & Support

Feature: Complete sieve kit list and accessory options

Data: Standard delivery 7–15 days, remote technical support

Benefit: Transparent investment, low risk, fast after-sales response

Contact VIBEPRO experts for a quote

Applications: Industries & Typical Materials

-

Food: Flour, Milk powder, Cocoa powder

-

Pharma: Pharmaceutical powders, Herbal powders

-

Chemical: Calcium carbonate, Silica, Resin powders

-

Minerals: Quartz powder, Clay, Ore fines

Technical Parameters

| Model | Layers | Sieve Diameter | Frequency | Tapping Rate | Noise |

|---|---|---|---|---|---|

| TS-200 | 1–7 | 200 mm / 8 in | 2900 rpm | 150 times/minute | <65 dB |

| TS-300 | 1–7 | 300 mm / 12 in | 2900 rpm | 150 times/minute | <68 dB |

| TS-400 | 1–6 | 400 mm / 16 in | 2800 rpm | 140 times/minute | <70 dB |

FAQ & Downloadable Guides

Q: What is the difference between tap sieve shaker and standard lab sieve shaker?

A: Tap sieve shaker adds tapping to vibration, ideal for cohesive or clogging-prone powders.

Q: Is it suitable for ultra-fine powders?

A: Yes, especially for powders below 75 μm.

Q: Does it require special sieve material?

A: Standard stainless-steel sieves are used; nickel-coated and custom meshes available.

Q: Is it noisy?

A: Optimized design keeps noise below 65 dB, safe for lab use.

Related product recommendations

VP-LTM Lab Testing Machine

VP-LCS Lab centrifugal separator

VP-LJC Lab Jaw Crusher

VP-LBMG Lab Ball Mill Grinding

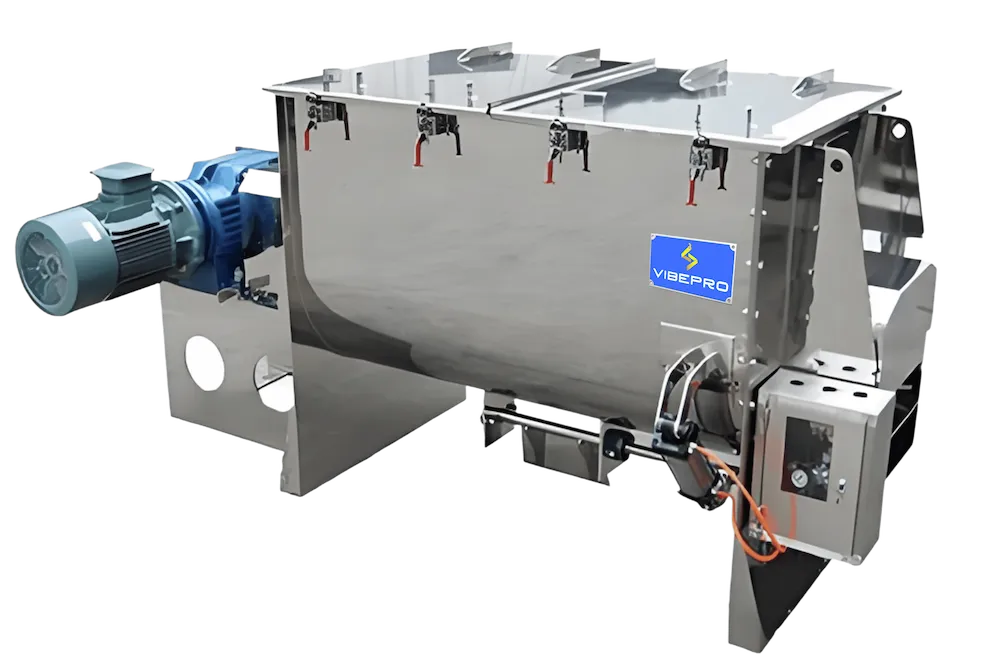

High-Uniformity Powder & Granule Mixer

Double-ribbon circulation

Low-shear design

Ribbon Blender Mixer · 100–10,000 L Capacity

VP-SPM Sesame Peeling Machine

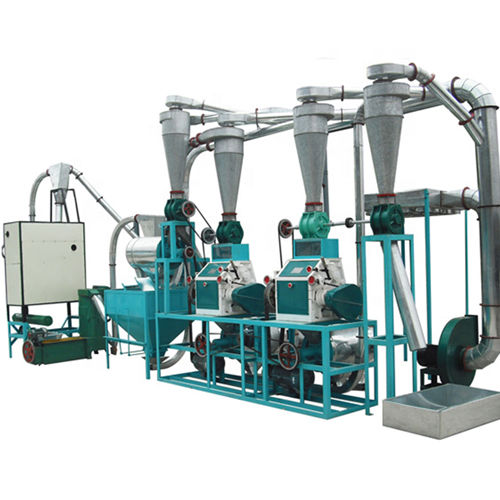

VP-GPM Grain Processing Machine

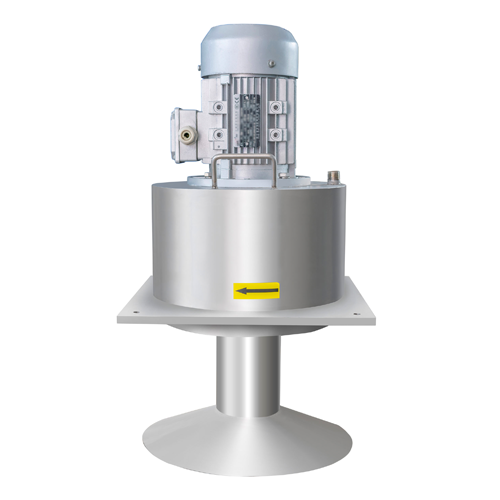

VP-FE Foam Eliminators

VP-SP Screw press

VP-PAFCM Pull action Filter Centrifuge Machine

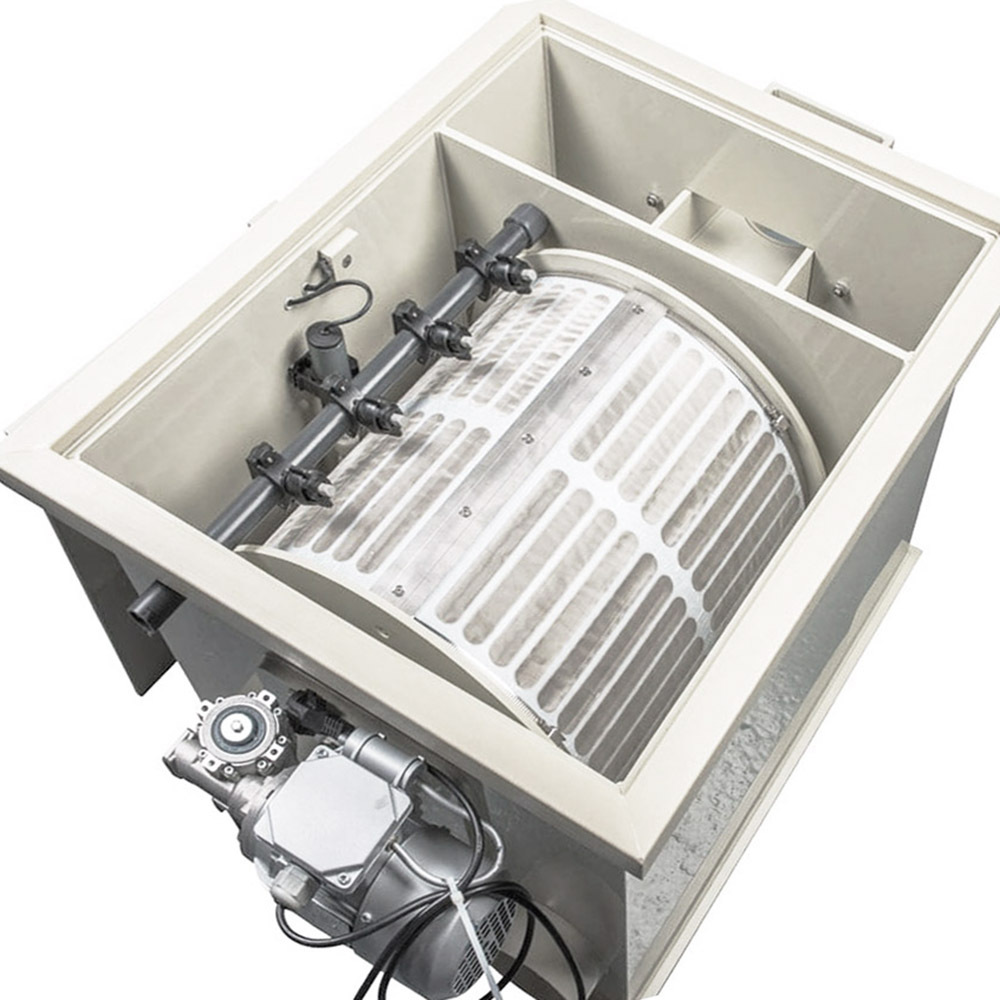

VP-MDS Microfilter Drum Sieve

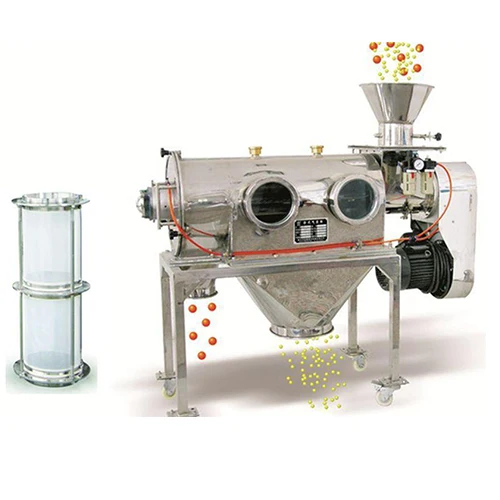

VP-ADS Airflow Centrifugal Drum Screen

VP-SGS Square Gyratory Screen

VP-DS Dewatering Vibrating Screen

VP-450FS Mini 450 Filter Sieve

VP-MCS Mining Circular Vibrating Screen

-

10 μm–20 mm particle size

-

1–8 layers test sieves

-

Low-noise < 60 dB

Laboratory Vibrating Sieve Shaker· Φ75 – Φ400 mm

VP-RDS Rotary Direct Discharge Vibrating Screen

Ultrasonic Vibrating Screen System

3D vibration motion

1–500 mesh size

Multi-layer design