-

Products

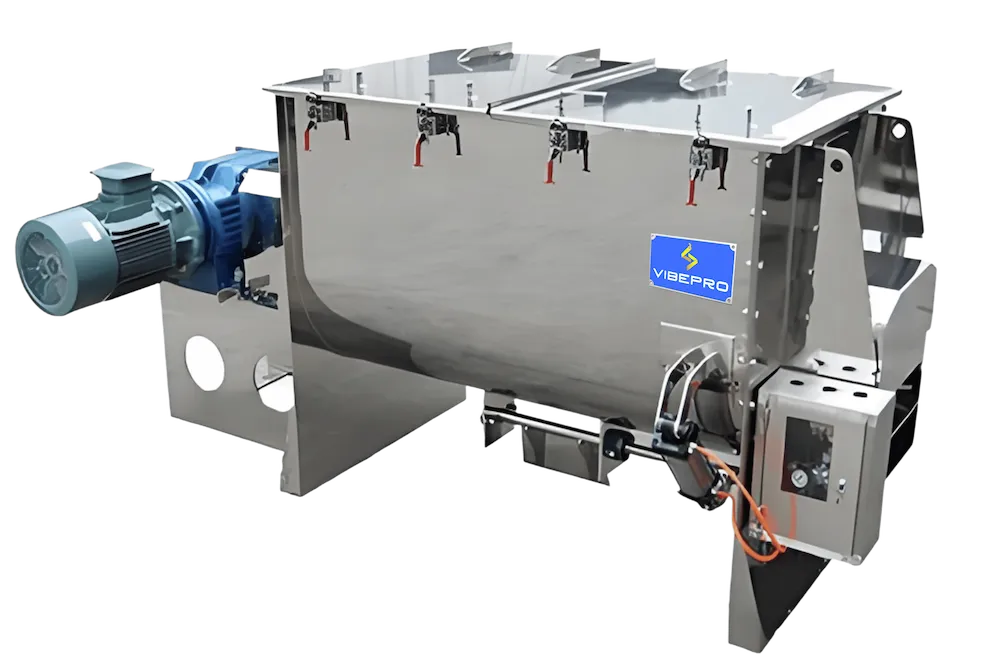

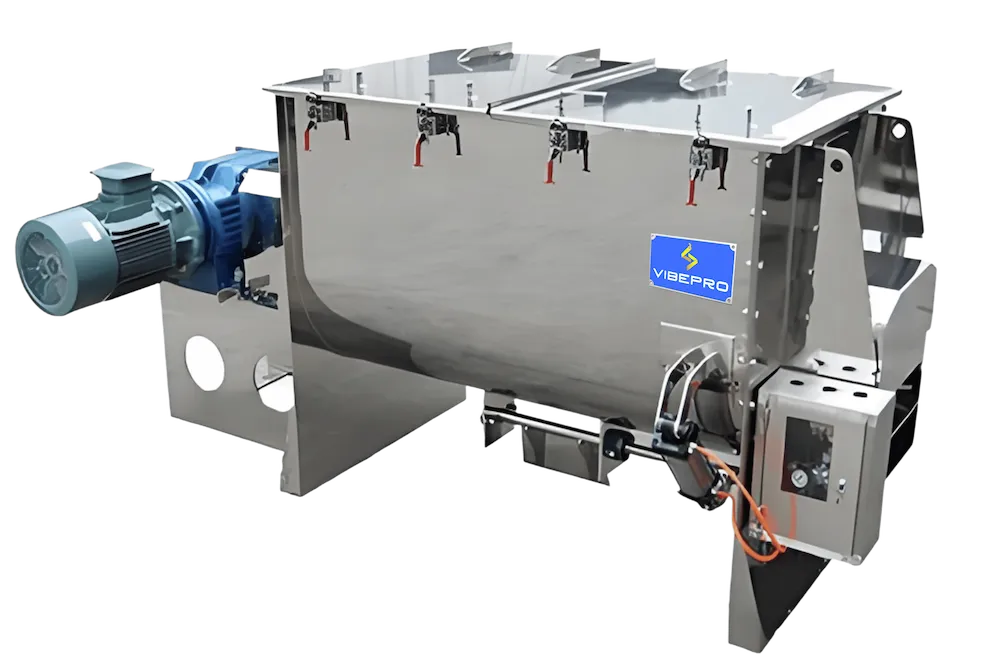

Ribbon Blender Mixer · High-Uniformity Powder & Granule Mixer

- Double-ribbon circulation; mixing uniformity RSD ≤ 5%

- Flexible Capacity — from 100 L to 10,000 L, suitable for small to large-scale production

- Low-shear design preserves fragile granules; optional vacuum & liquid spray

Ribbon Blender Mixer · High-Uniformity Powder & Granule Mixer

- Double-ribbon circulation; mixing uniformity RSD ≤ 5%

- Flexible Capacity — from 100 L to 10,000 L, suitable for small to large-scale production

- Low-shear design preserves fragile granules; optional vacuum & liquid spray

Product Overview

This ribbon blender uses double-helical ribbons to create radial and axial circulation for fast, uniform mixing of powders and granules. Compact and easy to clean, with options for vacuum and liquid spraying, it suits both dry blending and pre-granulation across food, chemical and pharmaceutical industries.

How It Works & Video Demo

Material enters through the top inlet; inner and outer ribbons drive axial and radial circulation for rapid convective mixing. Discharge via bottom valve; chamber is easy to clean and maintain.

Built Around Your Workflow · Practical Innovation · Total Cost Control

Why Choose Our Circular vibrating screen

Quantifiable Consistency (Mixing Accuracy)

Feature: Double helical ribbons generate both radial and axial circulation.

Data: Typical mixing uniformity RSD ≤ 5%, mixing time 8–20 minutes depending on material.

Benefit: Stable batch quality, reduced rework, and faster recipe adjustments.

Gentle Mixing for Fragile Materials

Feature: Low-shear operation with optimized ribbon design.

Suitable for: Spices, pharmaceutical pellets, fragile additives.

Benefit: Preserves particle integrity, reduces breakage and material waste.

Easy to Operate — Minimal Training Required

Feature: Intuitive control panel (PLC/touch screen optional), simple start/stop steps.

Data: Operators typically reach independent operation within hours of training.

Benefit: Less reliance on skilled labor, faster commissioning, lower training costs.

Low Maintenance & Predictable Spare Parts Cost

Feature: Standard bearings, replaceable ribbons, optional pneumatic discharge valve.

Data: Maintenance intervals typically 500–1,000 operating hours;Average maintenance time ≤ 2 hours; residue ≤1% with pneumatic valve.

Benefit: Reduced downtime, predictable spare part planning, lower maintenance cost.Customers can maintain themselves.

Flexible Integration & Custom Options

Feature: Multiple interfaces for feeders and packing lines, optional heating/cooling jacket, stainless steel 304/316 available.

- Capacity ranges from 100–10,000 L, supporting R&D → pilot production → mass production

Benefit: Smooth integration into existing lines without major modifications.

Compliance & Traceable Documentation

Feature: Detailed pricing, remote support, and a global spare parts network.

- Data: Provides a parts list, standard delivery schedule, and warranty; international “follow-the-sun” after-sales coverage.

Benefits: Comparable pricing, low risk, and rapid response to technical issues.

Contact VIBEPRO experts for a quote

Applications: Industries & Typical Materials

|

Applicable Industry

|

Typical Materials (for initial / primary crushing)

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Food

|

Flour

|

milk powder

|

spices

|

coffee

|

protein powder

|

|||||

|

Chemical

|

Detergent

|

pigment

|

resin

|

plastics

|

fertilizer

|

|||||

|

Pharmaceutical

|

Powdered medicine

|

herbal extracts

|

additives

|

|||||||

|

Construction

|

Cement

|

dry mortar

|

gypsum powder

|

quartz sand

|

||||||

|

Others

|

Animal feed

|

battery materials

|

ceramic powder

|

|||||||

Technical Parameters

| Model | Capacity (L) | Motor (kW) | Mixing Time (min) | Homogeneity (RSD) | Material | Discharge Type |

|---|---|---|---|---|---|---|

| RB-500 | 100–500 | 2.2 | 8–15 | ≤5% | SS304/316L | Butterfly Valve |

| RB-2000 | 500–2000 | 5.5 | 10–18 | ≤5% | SS304/316L | Pneumatic Valve |

| RB-5000 | 2000–5000 | 11.0 | 12–20 | ≤5% | SS304/316L | Pneumatic Valve |

FAQ & Downloadable Guides

Q1: Can Ribbon Blender handle liquids?

A1: Yes, small amounts of liquid can be added with a spray system for uniform distribution.

Q2: Can it handle heavy bulk materials?

A2: Yes, with customized motor and structure based on material density.

Q3: How to clean the blender?

A3: Quick discharge valves and optional CIP system allow fast cleaning between batches.

Q4: Vacuum option?

A5: Vacuum/low-pressure sealing available as an option.

Q5: Food/pharma grade & CIP?

A5: Available with 316L food-grade stainless steel and CIP options to meet GMP standards.

Related product recommendations

-

Combined tapping + vibration

-

Up to 7 sieve decks

-

Simulates manual tapping

Tap Sieve Shaker · tapping and vibration

VP-LMS Lab Magnetic Separator

VP-LJC Lab Jaw Crusher

VP-ELS Electromagnetic Levitation Sieve Shaker

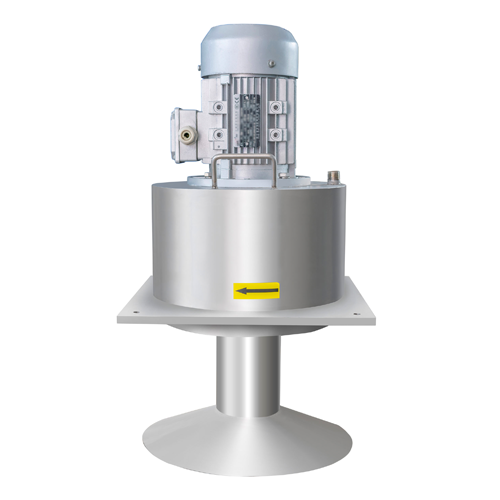

VP-FE Foam Eliminators

VP-SLS Solid Liquid Separator

VP-SP Screw press

VP-PAFCM Pull action Filter Centrifuge Machine

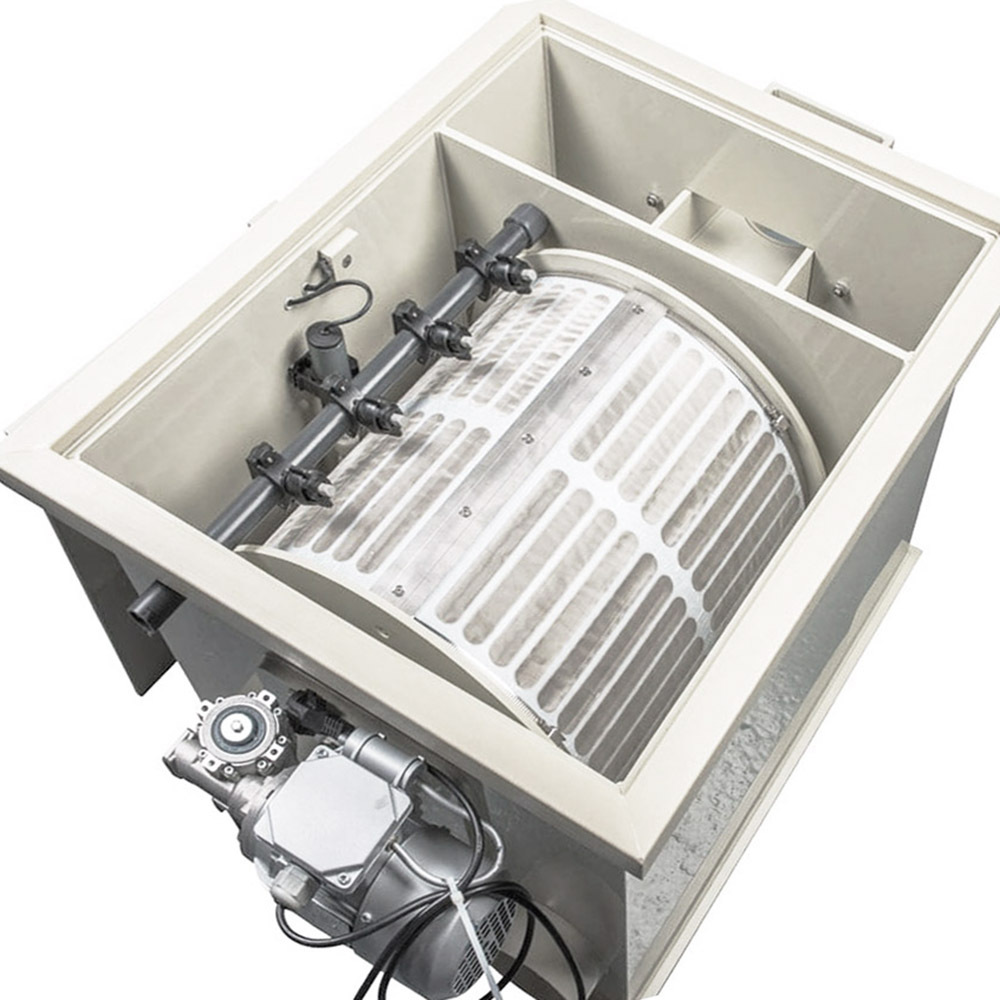

VP-MDS Microfilter Drum Sieve

VP-BFSL Bag Filter Solid Liquid Separator

Electric Heating Dryer· 50–300 °C Adjustable

VP-SGS Square Gyratory Screen

VP-DS Dewatering Vibrating Screen

VP-HFS High frequency Vibrating Screen

-

10 μm–20 mm particle size

-

1–8 layers test sieves

-

Low-noise < 60 dB

Laboratory Vibrating Sieve Shaker· Φ75 – Φ400 mm

VP-GS Flat Gyratory Sifter Screen

VP-RDS Rotary Direct Discharge Vibrating Screen

Linear Vibrating Screen

Ultrasonic Vibrating Screen System

3D vibration motion

1–500 mesh size

Multi-layer design