-

Products

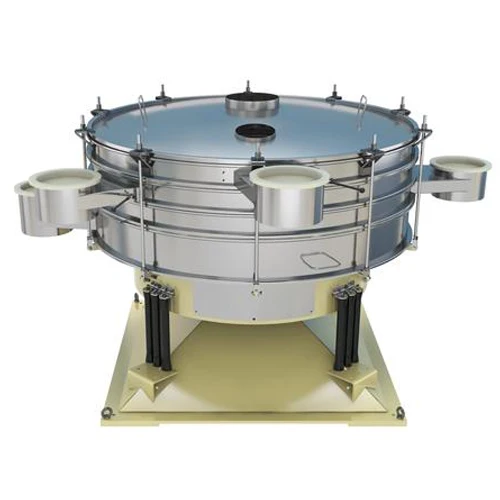

Circular Vibrating Screen · High-Precision Powder & Granule Sieving Machine

-

3D vibration motion, sieving accuracy up to 99%

-

Mesh size 1–500 mesh, fast screen change, high deblinding efficiency

-

Multi-layer design, up to 5 fractions in one pass

Circular Vibrating Screen · High-Precision Powder & Granule Sieving Machine

-

3D vibration motion, sieving accuracy up to 99%

-

Mesh size 1–500 mesh, fast screen change, high deblinding efficiency

-

Multi-layer design, up to 5 fractions in one pass

Product Overview

How It Works & Video Demo

The vibration motor with eccentric weights generates 3D motion (horizontal, vertical, inclined). Material spirals outward across the mesh, enabling precise grading or impurity removal. The demo video shows the circular and spiral material flow on the screen surface.

Built Around Your Workflow · Practical Innovation · Total Cost Control

Why Choose Our Circular vibrating screen

Durable & Low Maintenance

The steel frame and quickly replaceable screen mesh minimize downtime and reduce maintenance costs.

Easy to Operate

The quick-release connection design allows for single or multi-layer use, and screen replacement takes only 5 minutes, requiring minimal training for operation, which means less reliance on specialized labor.

Versatile Material Handling

Food, chemical, metal, metallurgy and mining – sugar, starch, salt, rice, beans, iron powder, aluminum powder, medicine powder, paint, wastewater, quartz sand, alloy powder, etc.

Compact & Space-Saving

Our circular vibrating screen is designed for small and medium-sized production lines. It is small in size and can be easily moved with wheels, making it suitable for narrow spaces.

Cost-Effective & Energy Efficient

Low operating costs, reduced energy consumption, and affordable wear parts contribute to a lower total cost of ownership, ensuring long-term savings.

Global Availability & Support

Fast access to spare parts, technical manuals, and remote support from anywhere in the world ensures continuous operation and peace of mind.

Contact VIBEPRO experts for a quote

Applications by Industry & Typical Materials

|

Applicable Industry

|

Typical Materials (for initial / primary crushing)

|

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Food Industry

|

Powdered sugar

|

starch

|

salt

|

rice flour

|

milk powder

|

soybean milk

|

egg powder

|

soy sauce

|

fruit juice

|

|

|

Chemical Industry

|

Resin powder

|

paint pigments

|

pharmaceutical powders

|

cosmetic ingredients

|

||||||

|

Metallurgy

|

Aluminum powder

|

lead powder

|

copper powder

|

alloy powders

|

electrode powder

|

refractory materials

|

||||

|

Mining & Minerals

|

Quartz sand

|

kaolin

|

heavy calcium carbonate

|

ore particles

|

mineral powders

|

|||||

|

Environmental & Others

|

Waste oil

|

wastewater

|

textile dyeing effluent

|

paper pulp

|

industrial additives

|

|||||

Technical Parameters

| Model | Diameter (mm) | Layers | Mesh Size | Capacity (kg/h) | Power (kW) |

|---|---|---|---|---|---|

| CZ-600 | 600 | 1–3 | 20–400 | 100–800 | 0.37 |

| CZ-1000 | 1000 | 1–4 | 20–500 | 200–1500 | 0.75 |

| CZ-1500 | 1500 | 1–5 | 20–500 | 500–3000 | 1.50 |

FAQ & Downloadable Guides

Q: Can it sieve liquid slurry?

A: Yes, with liquid filter mesh frame option.

Q: Does it support multi-layer classification?

A: Yes, up to 5 layers in one pass.

Q: Does the mesh clog easily?

A: Built-in bouncing ball or ultrasonic system prevents clogging.

Related product recommendations

-

Combined tapping + vibration

-

Up to 7 sieve decks

-

Simulates manual tapping

Tap Sieve Shaker · tapping and vibration

VP-LTM Lab Testing Machine

VP-LRK Lab Rotary Kiln

VP-LMS Lab Magnetic Separator

VP-LBMG Lab Ball Mill Grinding

VP-ELS Electromagnetic Levitation Sieve Shaker

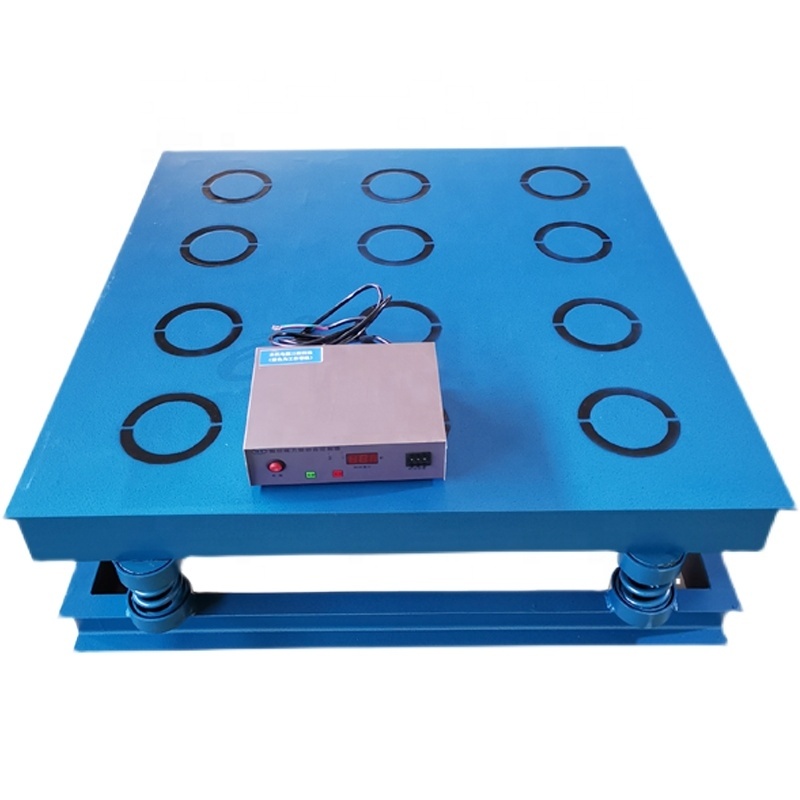

VP-VT Vibrating Table

VP-SPM Sesame Peeling Machine

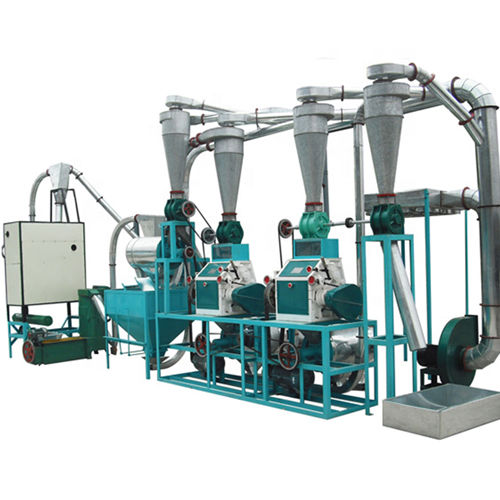

VP-GPM Grain Processing Machine

VP-FE Foam Eliminators

VP-CS Color Sorter

VP-BFSL Bag Filter Solid Liquid Separator

Electric Heating Dryer· 50–300 °C Adjustable

VP-SGS Square Gyratory Screen

VP-450FS Mini 450 Filter Sieve

VP-MCS Mining Circular Vibrating Screen

VP-GS Flat Gyratory Sifter Screen

VP-RDS Rotary Direct Discharge Vibrating Screen

High-precision sieving (up to 99% accuracy)