-

Products

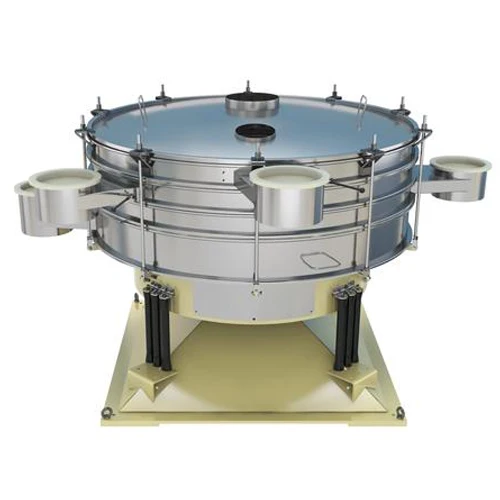

Laboratory Vibrating Sieve · Precision Particle Size Analysis & Lab Test Sieve Shaker

-

Covers 20 μm–20 mm particle size range for rapid distribution analysis

-

Stackable 1–8 test sieves for multi-grade screening tests

-

Compact, low-noise < 60 dB design, ideal for laboratory settings

Laboratory Vibrating Sieve · Precision Particle Size Analysis & Lab Test Sieve Shaker

-

Covers 20 μm–20 mm particle size range for rapid distribution analysis

-

Stackable 1–8 test sieves for multi-grade screening tests

-

Compact, low-noise < 60 dB design, ideal for laboratory settings

Product Overview

The laboratory vibrating sieve (test sieve shaker) is a precision device designed for small-batch material testing, particle size analysis, and laboratory sieving. Compact, lightweight, and easy to operate, it enables quick determination of particle size distribution. It is widely used in research institutes, laboratories, quality control, and small-scale production.

How It Works & Video Demo

Driven by a vibration motor or electromagnetic vibrator, the sieve stack is subjected to both vertical and horizontal vibrations. Materials are stratified through multiple sieves according to particle size, enabling particle size distribution analysis or impurity removal.

Built Around Your Workflow · Practical Innovation · Total Cost Control

Why Choose Our Laboratory Vibrating Sieve

Flexible Multi-Deck Sieving

Feature: Stackable 1–8 test sieves for flexible setups

Data: Delivers 2–9 particle size fractions in a single run

Benefit: Saves testing time, eliminates repetitive operations

Compact & Low-Noise

Feature: Compact structure with optimized noise reduction

Data: Operating noise < 60 dB

Benefit: Suitable for labs and office environments without interference

Easy Operation & Maintenance

Feature: Quick clamp mechanism,Intuitive operation panel

Data: Sieve changeover ≤ 1 minute,Operators can easily adjust the amplitude and sieving time

Benefit: Fast material switching, simple maintenance, low training cost

High-Precision Testing

Feature: Electromagnetic vibration drive with adjustable frequency

Data: Particle size analysis down to 20 μm

Benefit: Delivers reliable particle distribution data for research and QC testing

Strong and durable

Feature: Built with high-quality stainless steel or carbon steel materials.

Data: 316/304 stainless steel

Benefit: Not easily damaged after long-term use.

Compliance & Traceable Documentation

Feature: Clear sieve list, lead time, and calibration services

Data: Standard delivery within 7–15 days; remote technical support available worldwide

Benefit: Transparent purchasing, low risk, and global after-sales coverage

Contact VIBEPRO experts for a quote

Applications: Industries & Typical Materials

-

Food: flour, starch, sugar powder, coffee powder, spice sample testing

-

Pharmaceutical: medicinal powder, granules, raw capsule material analysis

-

Chemical: resin powder, ceramic powder, metallic powder laboratory tests

-

Education & Research: particle science studies, laboratory QC testing

-

Environmental: soil, sediment, solid particles in wastewater analysis

Technical Parameters

-

Suitable sieve diameter: Φ75 – Φ400 mm

-

Number of decks: 1 – 8 layers

-

Particle size range: 10 μm – 20 mm

-

Capacity: 0.02 – 5 kg/batch

-

Vibration frequency: 1400 – 3000 times/min

-

Power supply: 220 V / 50 Hz or customized

-

Noise level: < 60 dB

FAQ & Downloadable Guides

Q: Can it be used for liquid testing?

A: Yes, with optional wet sieving accessories.

Q: Is it compatible with standard test sieves?

A: Yes, compatible with Φ200 / Φ300 mm ISO / ASTM sieves.

Q: Do you provide calibration services?

A: Yes, factory calibration reports and third-party certification are available.

Related product recommendations

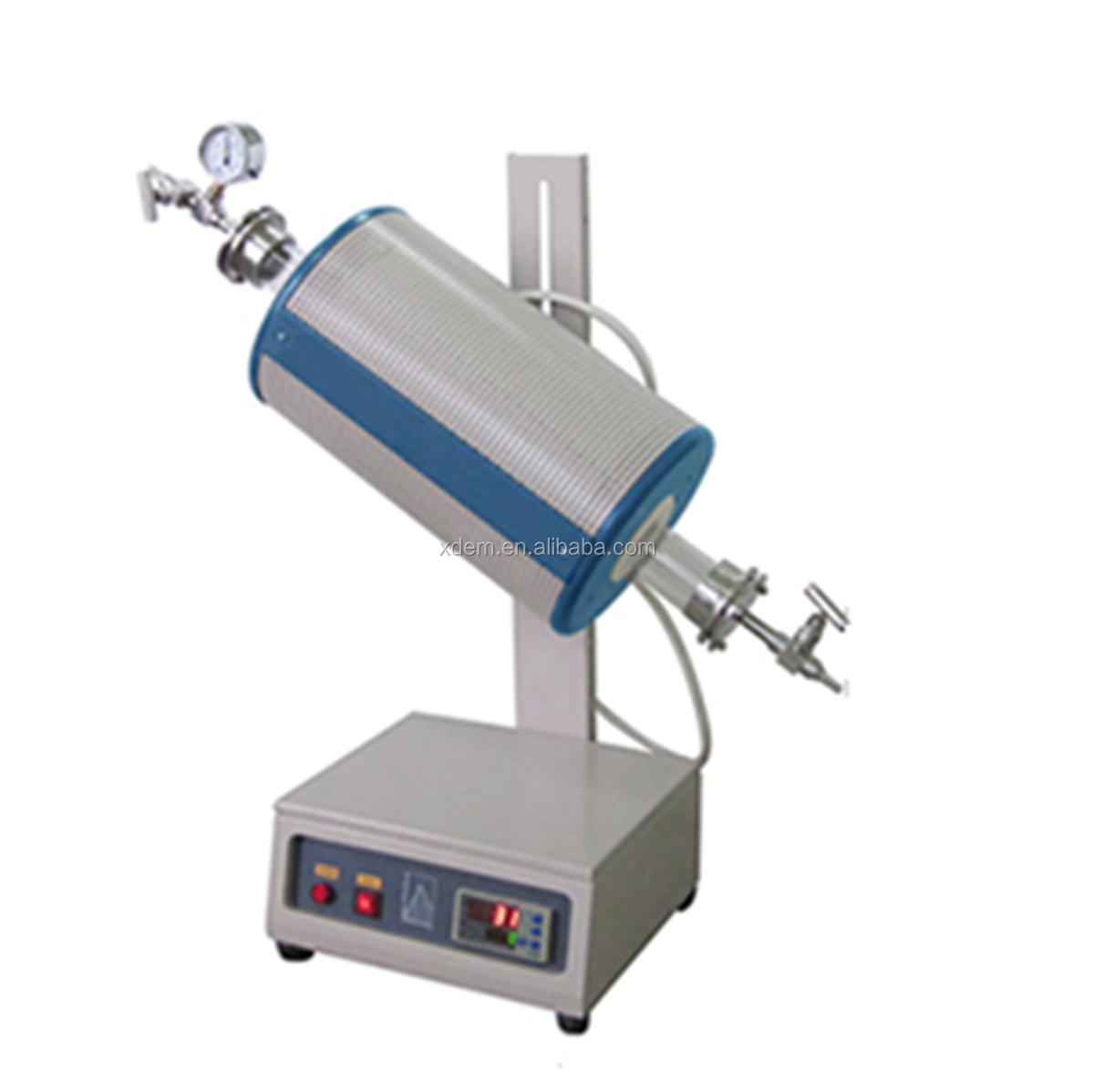

VP-LTM Lab Testing Machine

VP-LRK Lab Rotary Kiln

VP-LBMG Lab Ball Mill Grinding

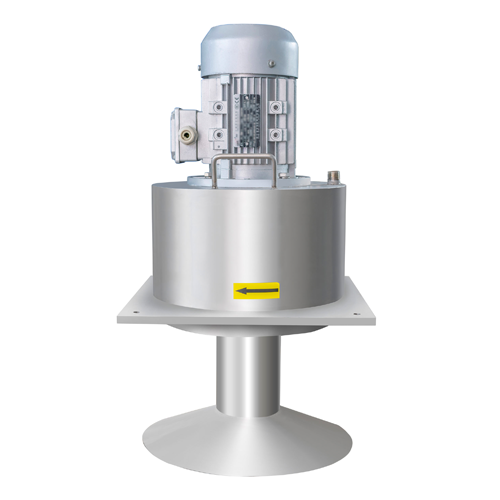

VP-SPM Sesame Peeling Machine

Screen Mesh

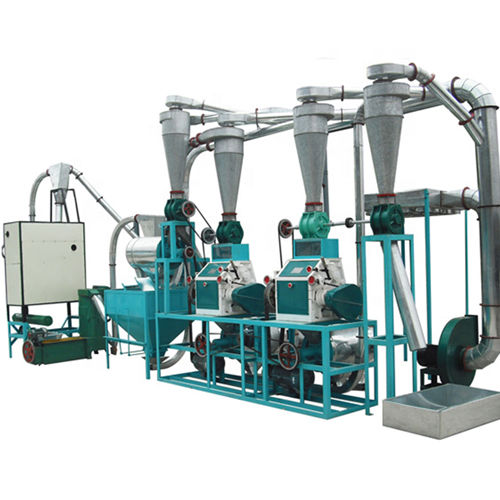

VP-GPM Grain Processing Machine

VP-FE Foam Eliminators

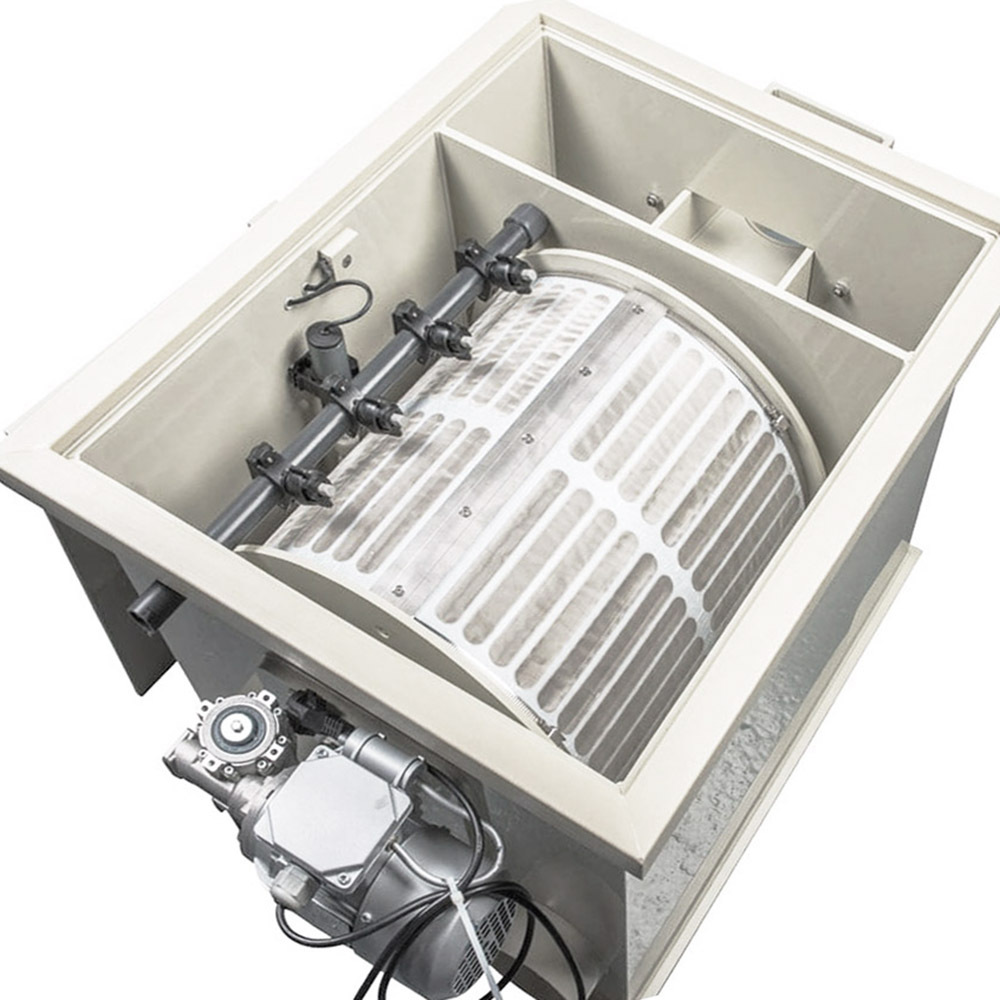

VP-SLS Solid Liquid Separator

VP-MDS Microfilter Drum Sieve

VP-BFSL Bag Filter Solid Liquid Separator

Small Jaw Crusher · 5-50mm Output

Screw Conveyor (Auger Conveyor)

VP-DS Dewatering Vibrating Screen

VP-HFS High frequency Vibrating Screen

VP-450FS Mini 450 Filter Sieve

VP-MCS Mining Circular Vibrating Screen

VP-RDS Rotary Direct Discharge Vibrating Screen

High-precision sieving (up to 99% accuracy)

Rotary Tumbler Screener · 99% screening accuracy

Ultrasonic Vibrating Screen System

3D vibration motion

1–500 mesh size

Multi-layer design